So I left you last time with a question - would me new steel-bodied extruder design print?

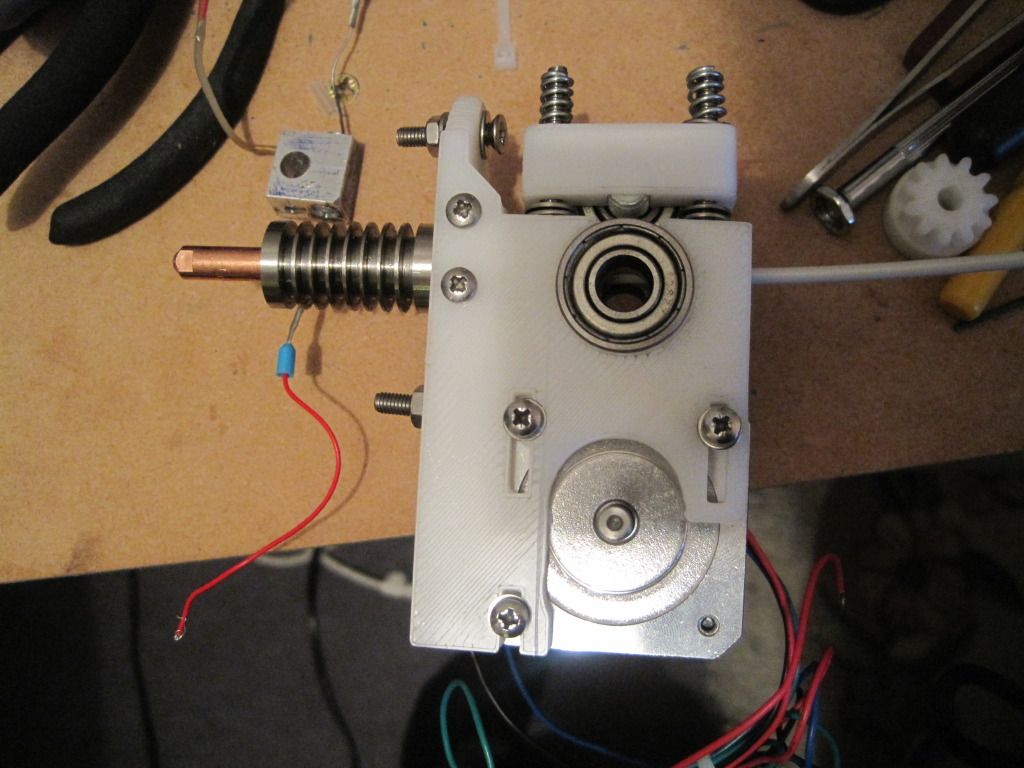

Well, I assembled it and mounted it to my extruder body:

I knew that this design would need some active cooling - stainless is conductive afterall, and so I mounted a 40mm computer fan on the carriage to blow air over the fins. I powered this from one of the sanguinololu's 12v plugs.

I loaded a 20mm cube into sfact on pronterface, and sliced at 0.3mm layers. I warmed up the hotend to 185, and pressed "print" - a scary moment, as it handed control of the machine over to the software and it started moving!

I got part of a raft, and not much more. It looked as if the extruder had jammed, and no matter what I tried I couldn't get it to move again. Finding the cause of the jam this time was fairly easy - I had put the fan on backwards! The heat had conducted up the barrel and without cooling had caused a jam.

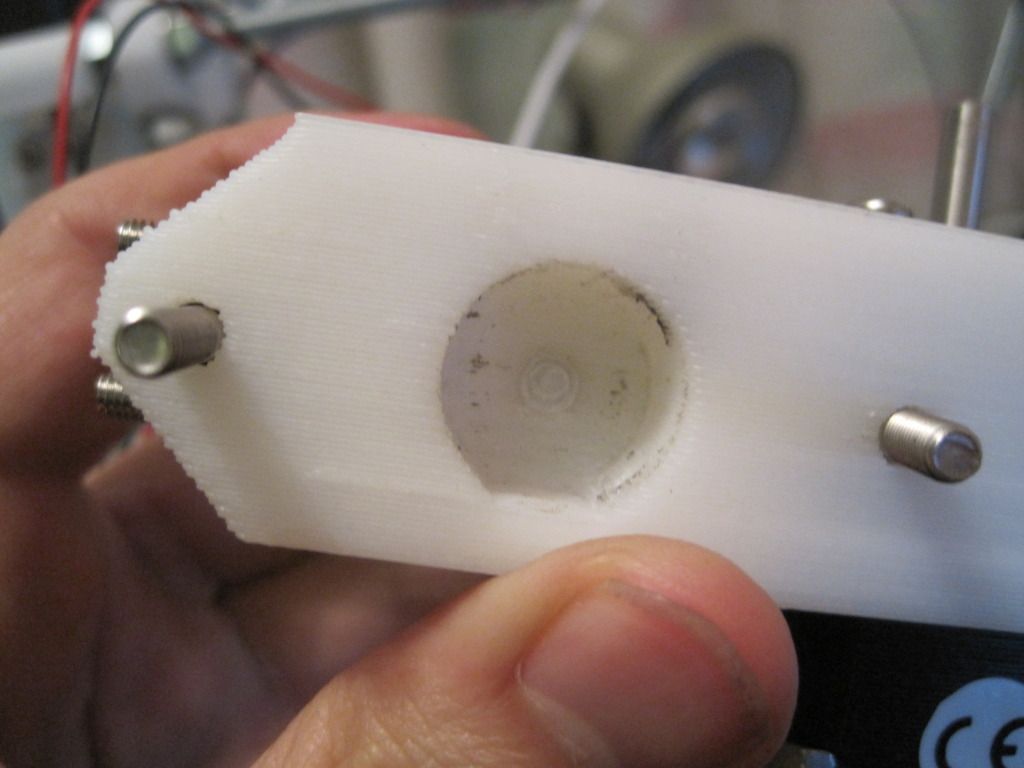

I stripped the entire assembly down. There was PLA dust in the hobbing on the bolt:

There was also material stuck in the PTFE, and in the nozzle:

This is where the jam occurred - right at the top of the barrier, as the feedstock enters the stainless.

The feedstock had expanded as it got hot, and jammed up. I had to use SERIOUS force to clear it - it had expanded some 20 or 30%!

I cleared out all the dust and jammed, overheated material and reassembled the entire thing. I reversed the direction of the fan, and tried to print again........

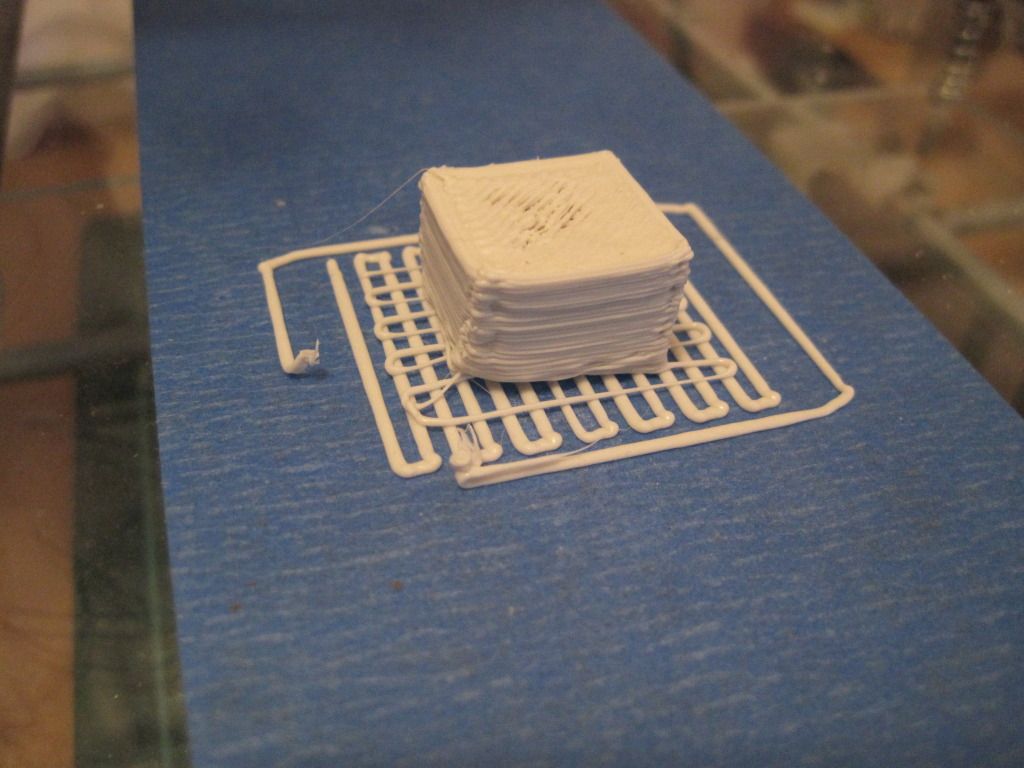

Finally, an object!

Sure its not perfect (the skirt isn't complete, and it is seriously undersized in height), but it IS an object, and I printed it!!

It was shortly after this high point that the printer went on it's holidays to the garage - we needed the workbench space for making Christmas cards. When it comes back, the fun will really start.

Next up: more printing!