I figured I'd start with the biggest bits first, and so went off to ebay and purchased a set of Prusa parts from Nophead. This set contains his redesigned z-azis couplers, which I will fit when the time comes.

I checked out the stepper motor page of the wiki, to try and help with choosing the right motors. I went for SOYO SY42STH47-1684B's in the end, from Zapp automation here in the UK.I had wanted the single-ended 1684A's, mostly because I thought they looked neater, but also because I wouldn't have to file flats in the shafts. I still might not, as I plan to use "pointed" grub screws to hold them in place. However I have a sneaking suspicion that they will not hold well enough, and so I might end up having to file the flats anyway.

I found a set of Prusa belts on ebay from threprapkitstore.co.uk, and I ordered a bed set of acrylic components from another ebayer. I decided to drill these myself, a decision that I may come to regret....

Several days and a couple of trips to Royston post office later, and I have my hands on a couple of boxes. Lets have a look in the one from Zapp:

The box is fairly compact, at about 15cms per side.

Inside, no surprise, are 5 stepper motors, wrapped in protective bubble wrap. The extra shaft isn't as noticeable as I had thought it might be. I know these are NEMA 17's, but somehow I had expected them to be a bit bigger. Oh well, size isn't everything.

Next up, the belt set:

Not much to say here: exactly what it says on the tin. These are the 5mm T5 drive belts that will move the X carriage and Y bed.

Now onto the big one - the reprapped parts from Nophead:

The box is a similar size to the one the steppers came in:

It's securely packed, and full to the brim.

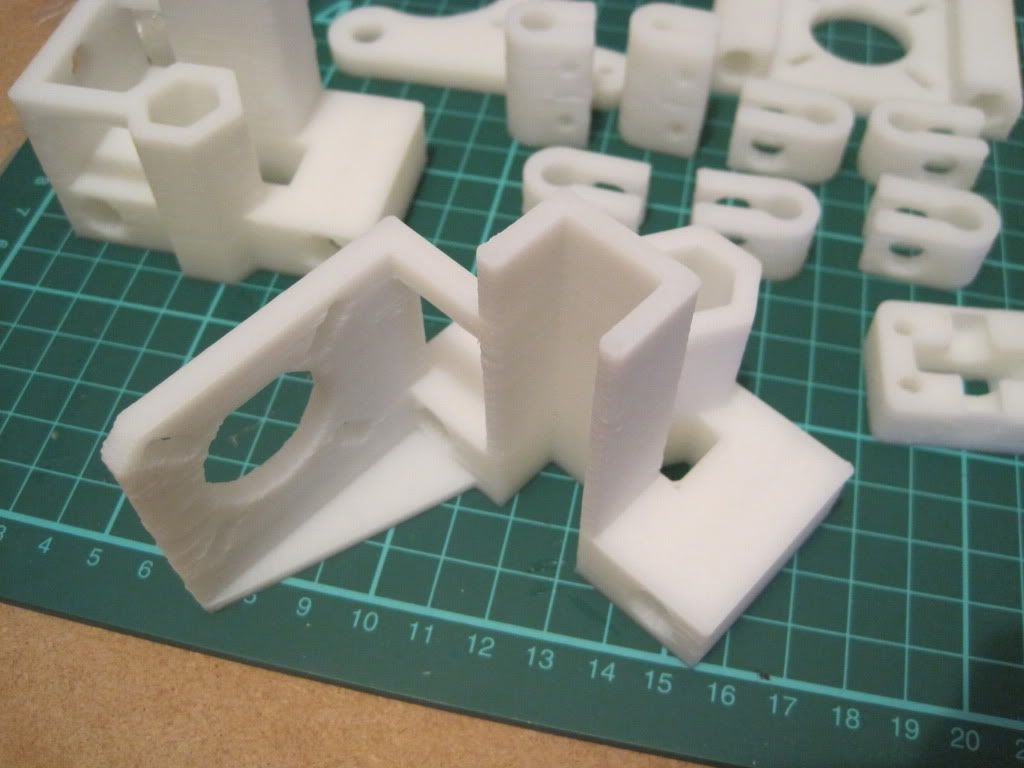

Here are the parts layed out. There seems to be quite a lot of them!

They have a very solid feel to them, and parts like the extruder body are quite heavy. If i can get my machine printing half as well as this I'll be pleased, and I'll be over the moon if I can match the quality of the gears - the big gear for the extruder is amazing! This is the biggest single piece, the motor mount for the X axis.

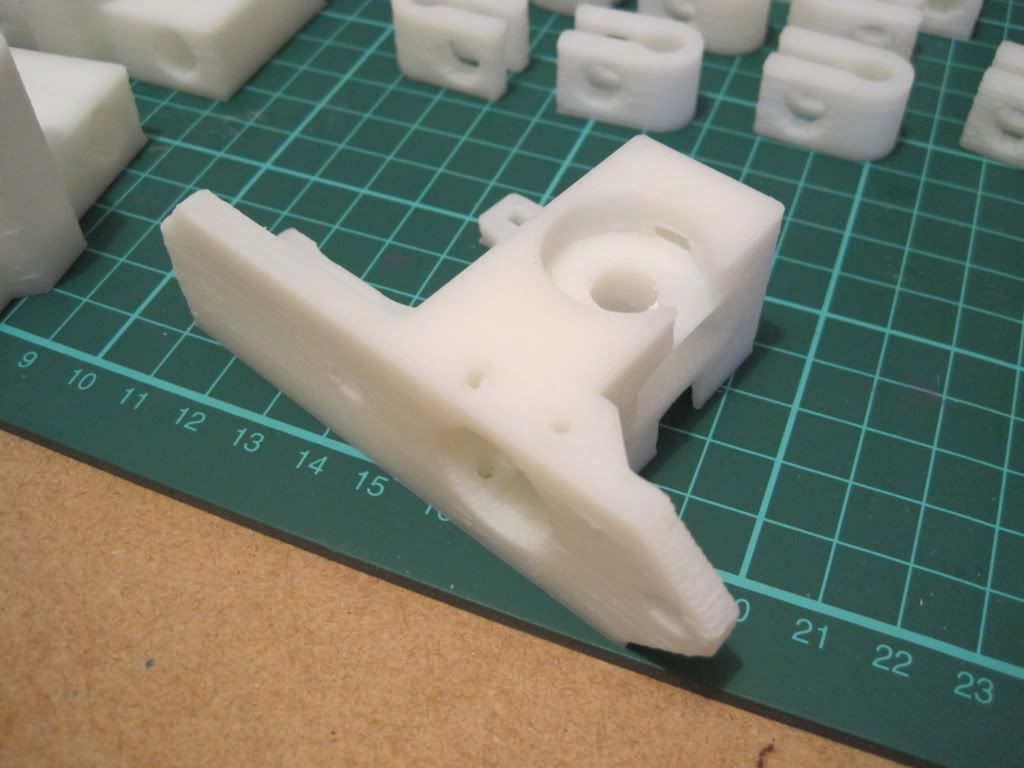

The extruder body is a great example of what makes 3d printing so awesome - this part would take lots of operations and several hours to machine out of a solid block of material. Here it can be done in a single operation, even the recessed bearing holder on the bottom of the body.

Next up - the joys of buying steel rod.

No comments:

Post a Comment